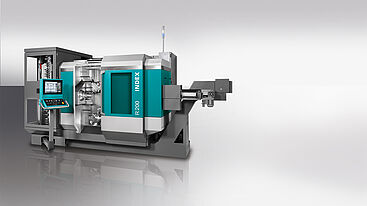

Turn-mill center R200 – simply convincing

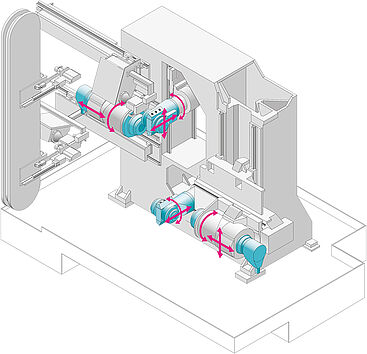

Increase productivity by two independent subsystems with full 5-axis capability

Machine highlights

Your benefits

- 5-axis machining on workpiece front and rear allows an extremely large variety of parts

- A total of 12 stationary turning tools for particularly high rigidity and cutting performance

- High cutting volume by powerful motorized milling spindles at 18,000 rpm

- Best damping and guiding properties of the milling spindles result in better workpiece quality and extended tool lives

- Outstanding dynamics due to high rapid traverse speeds and accelerations

- Already included: the operating system iXpanel iX4.0 with 18.5” touch screen based on Siemens S840D sl

R200 in the focus

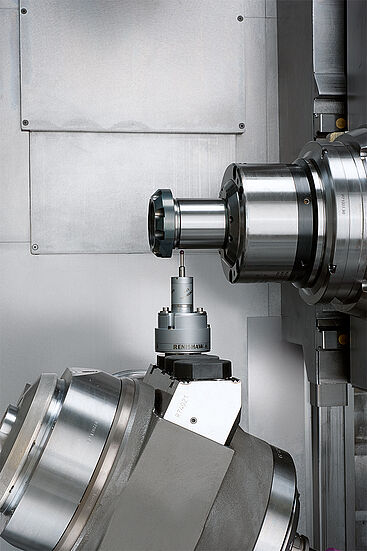

View into the work area

The unique design of the R200 combines exceptional rigidity of the moving parts with an impressive dynamic behavior at rapid traverse speeds up to 45 m/min.

At the same time, the design with vertical machine bed provides for optimized chip flow, so you do not have to worry about process reliability of the machine.

The magazine – all tools on board!

At a glance

- 80/120 tool pockets (HSK-T40 mounting)

- Shortest change cycles; chip-to-chip time only 4 s

- Simultaneous and independent loading of both milling spindles possible

- High degree of functional reliability due to standard tool magazine with chain design

WE NEED YOUR CONSENT!

This content is provided by Youtube.

If you activate the content, personal data may be processed and cookies set.

Accept